Dive into our overview below, and be sure to return for the complete review soon.

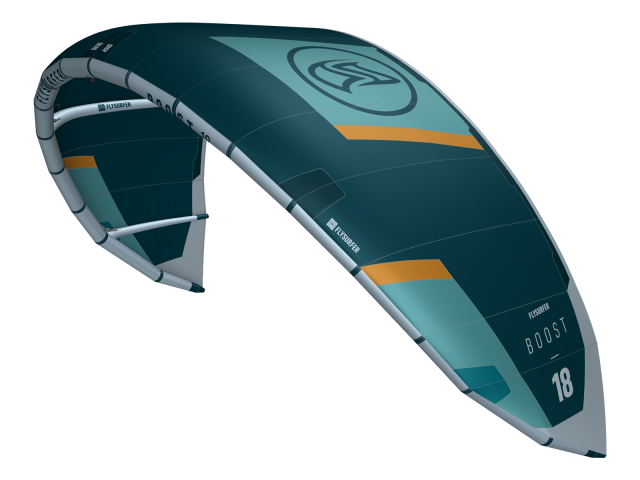

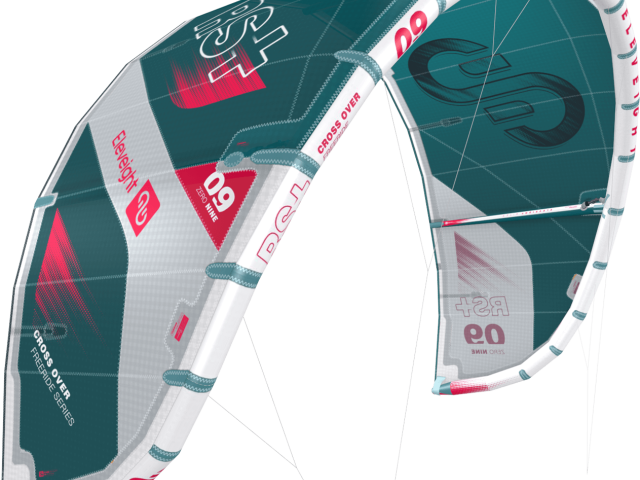

The ONE V2 is designed specifically for beginners and freeriders looking to progress safely. Its round profile incorporates three struts for added stability. It is user-friendly and intuitive, requiring no adjustments. It's a plug and play experience!

The ONE V2, featuring the Delta C-Shape kite, offers a fast, simple, and efficient relaunch. When the kite sits with the leading edge flat on the water, it automatically rolls over onto one wing tip. This allows riders to easily lift it out of the water and put it back up to the zenith, maximizing riding time and enjoyment.

The V2 has undergone extensive Sail Engineering work and now boasts new staggered seams and fabrics. The implementation of staggered seams on the trailing edge ensures a smooth profile. This breaks the tension line of the seams, resulting in a leveled canopy profile when the kite is fully powered. Additionally, the fabric's orientation towards tension is maintained.

Carefully chosen and positioned, the new fabrics on the kite enhance stability, balance, and durability, allowing for better control of the profile.

The inflatable structure of the kite is made with the new HITEX 158g, while the trailing edge uses HT80, a woven double ripstop high tenacity polyester. HITEX holds the kite's shape perfectly, and HT80 enhances stability. The kite also features the NANO 55g canopy, a micro ripstop polyester with a NANO coating and Plasma treatment for increased rigidity, resistance to elongation and tears, and durability.

The struts' reinforcements now have a sleek design thanks to the Kevlar strip on the top. This improves steering and maneuverability, reduces aerodynamic disturbances, and decreases overall weight when wet.

The ONE V2 maintains its performance abilities even through many take-offs and landings, sand rubbing, and water impacts. It remains balanced, retains power, and provides excellent feedback to ensure riders always know its position in the flight window.

With the ONE V2 and its excellent bar feedback, riders will always feel in control of their kite. The kite handles gusts perfectly and performs well in all wind conditions, delivering impressive depower even when overpowered.

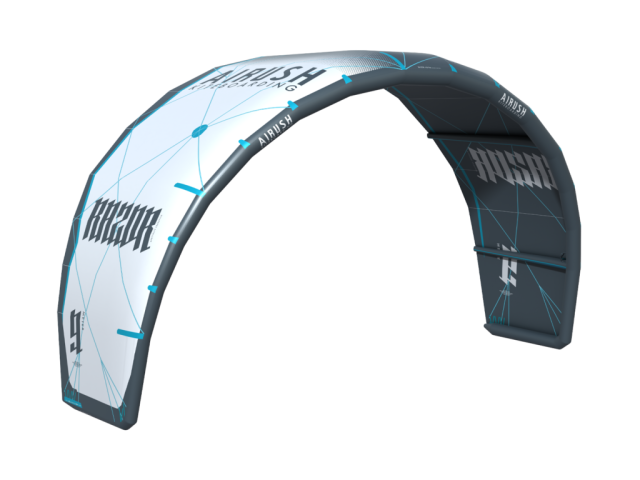

The DELTA C-SHAPE technology design, used by F-ONE for 15 years, ensures unmatched stability and responsive steering when fully depowered. It also allows for the option to connect the front lines higher on the leading edge of the kite.

The reactor inflation valve offers a high flow connection that easily locks the pump hose to the kite. This enables quick and effortless inflation and deflation at the push of a button, with high air flow rate between the struts and leading edge.

F-ONE's auto relaunch system quickly and efficiently releases the kite from the water, providing the perfect amount of traction. The combination of the C-Shape and Delta Pivot allows the kite to automatically roll over onto one wing tip, gliding towards the edge of the window for easy water relaunch.

TEIJIN's TECHNOFORCE™ is the reliable high-density polyester fabric used in the kite, known for its tear-stopping structure and durability. It is lightweight and has a proven track record.

The Force Frame, a solid Dacron structure, offers optimized durability without adding extra weight to the kite. This innovative design provides a sleek profile, enhancing efficiency and performance.

Staggered seams on critical parts of the kite, along with the fabric's orientation towards tension, ensure load control and maintain the original kite shape even under high loads. By using different cloth weights strategically, F-ONE has reduced the overall weight and improved the kite's optimization.

The HT80, a woven double ripstop high tenacity polyester, enhances stability and control of the kite's profile, ensuring resistance to elongation, tears, and increased durability over time.

The bridle is integrated in the lower part of the pulley, functioning in its axis. Pulleys can be easily removed independently from the bridle for replacements or adjustments, preventing bridle tangling with the streamlined leading edge tips.

The panels of the kite are now glued and sewn together for increased rip resistance. The trailing edge panels have an internal outline with a series of arches instead of a linear design. The center uses a double layer of canopy fabric instead of DACRON, spreading tensions and maintaining the kite's profile for improved stability and performance.

The kite's bladder is easier to remove and put back, simplifying bladder replacement.

The kite's struts are designed with a vertical cut to optimize the strength-to-diameter ratio, reducing weight while maintaining durability.

For over two decades, F-ONE has used Teijin's state-of-the-art cloth from Japan. Teijin has developed technologies and high-quality materials for F-ONE's kites, including double ripstop canopy cloth and durability treatments.

F-ONE has introduced a new Dacron 130g double ripstop, which saves weight without compromising strength. This results in a more reactive and lighter kite, particularly advantageous for larger sizes and light wind conditions.

Through extensive research and collaboration with fabric manufacturers, F-ONE now uses High Tenacity Polyester, a technical material known for its resistance to elongation and superior durability.

The HITEX fabric is coated with PLASMA, an eco-friendly technology exclusive to F-ONE's supplier. This coating guarantees increased fabric durability while using fewer chemicals in the finishing process, maintaining performance and stability.

Sail engineering is focused on controlling the kite's design and behavior during flight. By orienting fabric panels with regard to warp/weft direction and using staggered seams, load tensions are managed effectively, maintaining the desired shape for extended periods.

Woven fabrics with longitudinal (Warp) and transversal (Weft) yarns provide excellent resistance to elongation and strength when tension is applied along those yarns. By engineering load control paneling to ensure warp/weft orientation, the fabric and seams can better receive tensions and maintain the original kite shape.

The trailing-edge panels and seams bear most of the back lines' tension in the kite. Staggered seams balance the stiffness between seams and fabric, distributing the load over a wider area and preserving the original shape under high loads.

F-ONE uses four different cloth weights, ranging from 52 to 155gr/m². This sail engineering approach allows for shape control and load tension without the need for heavy fabrics or bulky designs, resulting in a lighter and optimized kite.

The HT80, a woven double ripstop high tenacity polyester, enhances stability and profile control.

Bridle and pulley elements can be easily adjusted, replaced, or interchanged.

The leading edge tips have a reduced diameter for streamlined performance and come equipped with a strap to prevent bridle tangling.

Stronger panel assembly ensures the canopy is highly resistant to ripping, with panels glued and sewn together.

The internal outline of the trailing edge panels features a series of arches for improved performance.

The center utilizes a double layer of canopy fabric for enhanced tension spreading, maintaining the profile, stability, and performance.

Bladder management is made more convenient for replacement or repair.

The struts are designed to optimize strength without sacrificing diameter.

F-ONE has partnered with Teijin for over two decades, benefitting from their expertise, technology, and quality materials. Teijin's advancements in double ripstop canopy cloth and durability treatments have significantly contributed to F-ONE's kites.

A new Dacron 130g double ripstop has been developed in collaboration with Teijin, resulting in weight savings without compromising strength. This enables a more reactive and lightweight kite, particularly advantageous for larger sizes and light wind conditions.

For more information visit F-ONE KiteboardingRelated

By IKSURFMAG