Dive into our overview below, and be sure to return for the complete review soon.

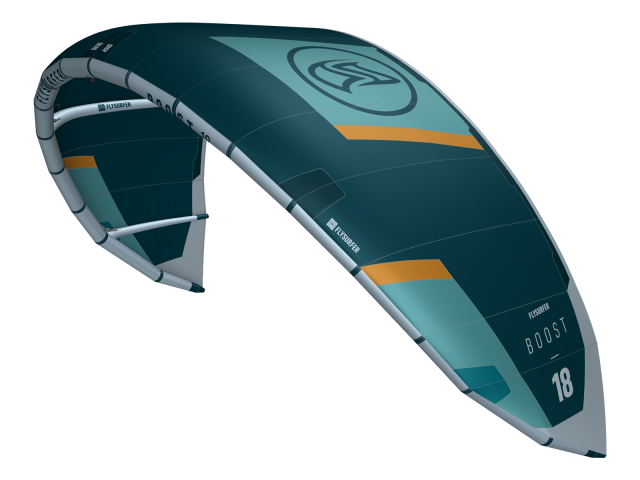

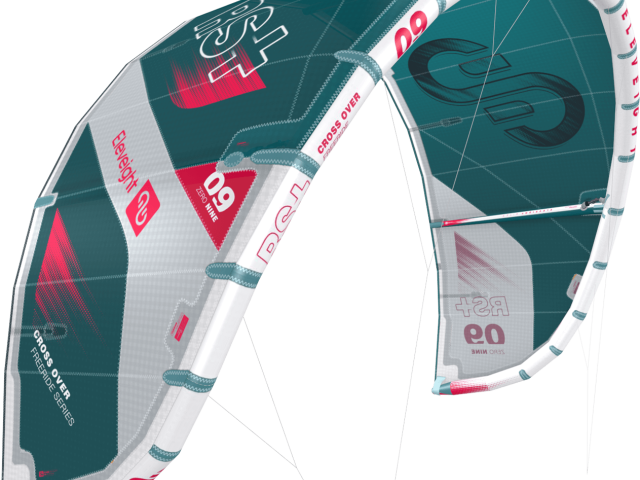

The BREEZE continues to be the most user-friendly one-strut kite available on the market, boasting impressive light wind capabilities and effortless control. The fourth version of this kite has undergone extensive Sail Engineering work, incorporating new fabrics and staggered seams to enhance its performance and durability.

The BREEZE V4 is designed for those seeking a lightweight setup that offers exceptional handling and performance in low-wind conditions. With a size range from 7m² to 17m², it is the ideal kite for light-wind freeriding and foiling in any weather conditions. Its stability and lightness also allow for low-wind wave riding.

Staggered Seams have been implemented on both the leading and trailing edges of the kite to create a sleek profile. By breaking the tension line of the seams, the entire canopy profile is leveled when the kite is fully powered. The fabric's orientation towards tension is also maintained.

The inflatable structure of the BREEZE V4 utilizes HITEX 158g, a brand-new high tenacity polyester that offers excellent resistance to elongation, resulting in greater durability and performance.

This kite features the new NANO canopy 55g, a micro ripstop polyester that is used throughout the entire canopy. It benefits from a NANO coating and a Plasma treatment process, which increase rigidity, resistance to elongation and tears, and overall durability.

These new fabrics and their strategic placement on the kite provide better control of the canopy profile, resulting in improved stability, balance, and extended lifespan.

The strut reinforcement now includes a smooth Kevlar strip on the top, enhancing the kite's steering and maneuverability, reducing aerodynamic disturbances, and decreasing overall weight when wet.

When in the air, the BREEZE V4's intuitive flying characteristics allow riders to focus on their ride without worrying about the kite. This makes it suitable for both beginner and advanced riders.

The handling of the BREEZE V4 has been finely tuned across the entire size range. Larger sizes offer incredible responsiveness for maneuvering, while smaller sizes are optimized for stronger winds, providing speed control and stability during foiling. Relaunching, including reverse launch, is instinctive and easy, even in very low winds.

The kite is designed to work with a low V setup. If you're in search of a lightweight, one-strut kite that can deliver a great experience even in eight knots of wind, the BREEZE V4 is the obvious choice. Enjoy countless possibilities with this kite!

The DELTA C-SHAPE technology design of the BREEZE V4 offers exceptional stability and steering response when fully depowered. It also allows for connecting the front lines higher on the leading edge of the kite.

The DELTA C-SHAPE design is a patented feature that F-ONE has been using on all their kites for the past 15 years. The shape was developed to optimize the kite's aerodynamic performance and depower capabilities. It allows for increased canopy area in the middle sections, creating more projected area, while ensuring the kite remains responsive and fluid.

The reactor inflation valve provides a quick and easy high flow connection that twist locks the pump hose to the kite. This allows for fast and effortless inflation and deflation at the push of a button. It also enables a high air flow rate between the struts and leading edge.

F-ONE's auto relaunch feature makes getting the kite back in the air quick and easy. When the kite is sitting with the leading edge flat on the water, its C-Shape and Delta Pivot enable it to automatically roll over onto one wing tip. The kite will then glide towards the edge of the window, ready for quick and effortless water relaunch.

The brand-new F-ONE design innovation offers an incredibly sleek profile, resulting in increased efficiency and sharper performance.

Original staggered seams have been implemented on critical parts of the kites, breaking the tension line and leveling the canopy profile when the kite is fully powered.

The micro ripstop polyester 55g used on the SWING V3, CWC V2, BREEZE V4, and ONE V2 canopies is designed to withstand the elements. With NANO coating and Plasma treatment, it provides increased rigidity, resistance to elongation and tears, as well as improved durability. The use of Plasma technology reduces chemical usage during the finishing process, making it an eco-friendly option without compromising performance and stability.

To meet the specific needs of wing and kite development, F-ONE has developed HITEX, a new high tenacity polyester. This material, available in 158g and exclusively for F-ONE in 178g, offers incredible resistance to elongation, increasing the durability of wings and kites.

HITEX is an innovative high tenacity polyester fiber with enhanced weaving and coating, improving the fabric's resistance. It is used throughout the inflatable structure of wings and kites, handling high pressures during inflation, and providing performance and durability. Sail Engineering work ensures the precise placement of different weights of HITEX for absolute control over the kite's shape.

By working closely with fabric manufacturers, F-ONE has chosen High Tenacity Polyester, a technical material known for its resistance to elongation and superior durability.

HITEX is coated with PLASMA, an exclusive innovation from F-ONE's supplier that guarantees increased fabric durability. Combined with high tenacity polyester fibers, HITEX offers exceptional durability, making it the most long-lasting material on the market.

Sail engineering plays a crucial role in controlling the design and behavior of F-ONE kites while flying. The goal is to master the kite's loads and maintain the desired shape for as long as possible.

Woven fabrics consist of longitudinal 0° yarn (Warp) and transversal 90° yarn (Weft). By applying tension along these yarns, fabrics can resist elongation and handle loads efficiently. However, when tension is applied at different angles, the fabric may deform and stretch.

During load control paneling, F-ONE ensures that fabric panels are warp/weft oriented, allowing the load path to run through the yarns. This positioning ensures that the fabric and seams can handle tensions and maintain the kite's original shape.

Most of the kite's back lines tensions are distributed through the trailing-edge panels and seams. As seams are stiffer than the fabric they join, they can strain under loads and deform the profile. Staggered seams balance the stiffness between seams and cloth, distributing the load over a wider area to maintain the original shape under high loads.

F-ONE sails utilize four different cloth weights, ranging from 52 to 155gr/m². Sail engineering enables control over the shape and tension without the need for heavy fabrics or bulky designs, resulting in a lighter and optimized kite.

When sheeted in, the back line is released, and the forces transfer to the front connector. This increases bar pressure and reduces maneuverability, providing a progressive bar feel similar to sheeted-out back connectors. When sheeted out, the kite tilts and becomes stiffer, with tensions concentrated on the trailing edge. This leads to reduced flapping, improved starts, and enhanced maneuverability with less pressure.

High tension tuning, achieved by sheeting out with the upper knot tuning (1), increases maneuverability and reduces bar pressure. Low tension tuning, achieved by sheeting in with the lower knot tuning (2), decreases maneuverability and increases bar pressure.

The panels of the canopy are now glued and sewn together to create a stronger assembly, making the canopy more resistant to tearing. This feature also makes it easier to remove and replace the bladder when needed.

The leading edge tips of the kite have a reduced diameter to minimize drag and are equipped with a strap to prevent bridle tangling.

The internal outline of the trailing edge panels features a series of arches instead of a linear shape.

In the center, a double layer of canopy fabric replaces DACRON, improving the distribution of tensions, maintaining the profile, and enhancing stability and performance.

The kite's struts have a vertical cut, optimizing the strength-to-diameter ratio.

Videos

For more information visit F-ONE Kiteboarding

Related

By IKSURFMAG