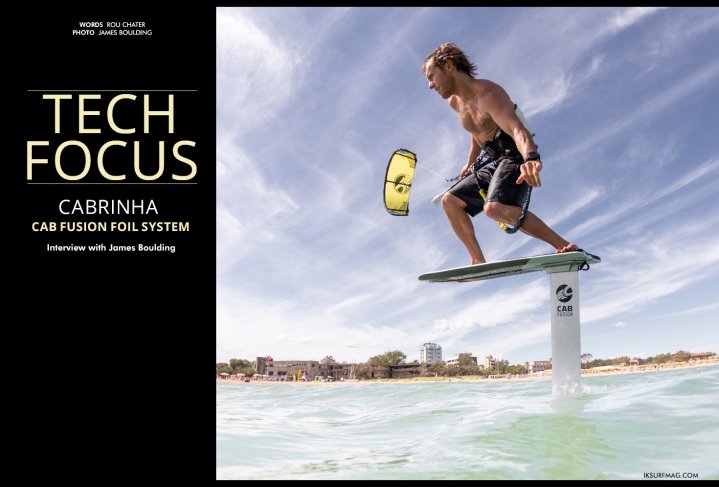

Tech Focus - Cabrinha

Issue 83 / Fri 16th Oct, 2020

We speak to James Boulding from Cabrinha about the new Cab Fusion foil system, a new innovative connection system designed to future proof the foils for any sport.

Cabrinha - Cab Fusion - Interview with James Boulding

The whole hydrofoil system has been redesigned from the ground up across all your sports, kite, surf and wing, what was the need for the change, why did you decide to change the system after the new release last year? Was it hard to come up with a concept that works across all disciplines?

This was actually the main part of the brief to begin with. Cabrinha wanted a modular system where owners can interchange wings, masts and fuselage sections to tailor their equipment to whatever sport they want to go out and do. We’ve been seeing people using bigger wings for surf foiling as well as big boards for wingsurfing so there are some huge torsional forces involved. It was clear early on that there was a need to futureproof the Cab Fusion system so that whichever directions the sports take the equipment platform can cater for this. We negated the issues of directly connecting wings to the fuselage with screws by seamlessly integrating the wing sleekly and efficiently to the front part of the fuselage where a huge amount of torsional stress goes through. It also became very important that playing around with the length of the fuselage was key to customising your ride for the different sports and a trend seen happening out in Maui. The Fusion system allows you to easily change the rear section of the fuselage at a very cheap cost without needing to buy a whole new fuselage. For winging we’ve seen guys choosing longer fuselage options whereas for kiting, slightly shorter rear sections are better if a more agile and carvy characteristic is desired. This modularity extends to the mast options too with carbon and alloy offerings. Whichever direction wings go in, the system is ready to take on this change without anybody needing to buy new parts for the rest of the system. All of this combines into the futureproof principle that is at the heart of this system.

Who worked on the design aspects and how long was it in testing?

The majority of the brand staff & some key riders have been involved in this project. It’s been a major undertaking we’ve worked on as a brand for the last year and it perfectly suits some of Cabrinha’s key engineers, staff, even new owner of the company, Jon Modica who is a self confessed foil geek at heart. The sale of Cabrinha out of Pryde Group back in February has brought an injection of finance, tools and support to push innovation and bring product to market faster. The Fusion system is the first example of this in action and gives you an idea of what the future will look like for the brand under its new ownership. Spearheading the Product Development Department, is Lars Moltrup and together with Mechanical Engineer and designer, Brodie Sutherland, there has been intensive work done on the Fusion system. Based in Hood River, Brodie runs his fabrication workshop, which is perfectly suited to churning out foil wings and it is here where a lot of Cabrinha’s samples are first designed, built and tested. In Hawaii, the home of Cabrinha’s main test team, the process grows exponentially to encompass some familiar names. Pete Cabrinha was at the pioneering stage of foil development, riding massive waves like jaws on heavy home built setups utilising snowboard bindings and early home-made foil setups in the late 90’s. Since the recent foil resurgence he’s been at the cutting edge of the testing process together with Product Development Manager Lars Moltrup. You can usually find them each morning before work down at the harbour in Maui, the perfect place for testing foils. A full time addition to the foil test team this year is Keahi de Aboitiz. Keahi has spent the last few years carving out a very enviable existence foiling the outer reefs on Oahu while breaking the internet at the same time with his videos of this. Now, fully integrated into the Cabrinha development process he brings a valuable skill set to the table when it comes to fine tuning wings fresh from the press.

One recent new area that has injected insight into the Fusion foil program has been a collaboration between Cabrinha and a team of research scientists in Norway at SINTEF and Trondheim University(NTNU). The team have been performing various tests in their cavitation tunnel to give hydrodynamic feedback on the wing aerofoils and other design aspects. This valuable data helps give design feedback to Cabrinha’s R&D team while also embarking on a partnership where the SINTEF team can gain valuable data through experiences and problems that occur in real life foiling. This information and data sets give the team a chance to test and validate their numerical simulations in real life situations and products already in the market. In one particular area of research there is specific interest in foils operating very close to the water surface, something that foilers can become all too aware of. The moment when the wing tip breaches the surface on a tight turn or when the wing breaches with too much back foot pressure. All these instances that can easily throw riders off are areas of research that the scientists and the brand collaborate on expanding their understanding. It allows for a more in depth understanding of the performance of the Fusion system and it allows for a design process where iterations of the design can be numerically validated. It brings a new level of theoretical and practical knowledge to the Cabrinha hydrofoil design process.

What are the main advantages of the new system for the end consumer?

The key advantages of the system is stiffness, modularity and efficiency. Every connection has been redesigned to maximise stiffness. This is really where you notice the difference between other options on the market. The integrated carbon front wing & fuselage connection means that when you lean into a turn you get an incredible response with no give in the system. The new mast construction and deep fuselage to mast connection add to this for an ultra-stiff setup. It’s all about performance and something that is very noticeable the first time you jump on it. Wingsurfing, surf foiling and kite foiling are exploding at the minute and it’s got everyone amped on putting this product together so that riders aren’t worried about the durability of the product when trying new things.

Helicoil’s are being used to avoid oxidisation between the materials, how reliable are these?

Components like the new helicoils just go to show the level of detail and thought that have gone into this system. It may seem a small part but how many people out there are sick of having their screws seize up, stripping threads or getting components stuck on? This brings a new level of durability to our Fusion Hybrid system. The kits also come with premium titanium coated screws, which further minimise corrosion.

When is the Cab Fusion system going to be available in the shops?

It’s currently shipping from the factories and on its way to our network of global distributors and will be available in the shops within the next few weeks.

Videos

By Rou Chater

Rou has been kiting since the sports inception and has been working as an editor and tester for magazines since 2004. He started IKSURFMAG with his brother in 2006 and has tested hundreds of different kites and travelled all over the world to kitesurf. He's a walking encyclopedia of all things kite and is just as passionate about the sport today as he was when he first started!