Intriguing Beings - Leo Koenig

Issue 105 / Mon 24th Jun, 2024

Rou Chater sits down with Leo Koenig, the founder and CEO of WOO Sports, to discuss the highs and lows of a company that changed the kiteboarding game. If you’ve never heard of the WOO, then there is a chance you've been living under a rock. The small blue box known for bringing joy and pain has likely been attached to your board during the last ten years or so. You might even have some stuck here if you are a real fan.

Sitting down with Leo was a great opportunity and an interesting conversation. I recommend you listen to the full episode on Spotify or wherever you get your podcasts. It’s an insightful journey into Leo's passion for making kitesurfing fun. There is no denying that the WOO is a bit of a marmite device. You either love it or hate it, likely depending on your own experiences with it over time.

The WOO 4.0, a groundbreaking product that entered the market a few months ago, is being acclaimed as the ultimate WOO. With its new and improved hardware, the company believes it has not only met the physical demands of kiteboarding but also that the device now consistently delivers impressively accurate results.

WOO was established back in 2013, with the first WOO hitting the market in 2015. The brainchild of Leo, he was determined to definitively answer the question of who jumped the highest. At that time, technology was just beginning to emerge, and this could make this a reality. Fast forward to now, and technological advances have enabled WOO to create a product they truly stand behind, not only in terms of durability but also accuracy, which has always been the company's goal.

I asked Leo about the origins of the business and his background in mechanical engineering, which he studied at university.

You don't start your career thinking you will do something entrepreneurial—at least I didn't. But I studied mechanical engineering and always had an interest in technology, physics, and understanding things. Back then, I lived in Boston and worked two different jobs. One was in product design. So, I followed my true engineering background and everything I've been taught at university.

I did that for a year and a half, but it was a bit boring. I don't want to say boring, but you don't get to make design decisions as an engineer. You're just executing someone else's ideas, and you always have in the back of your mind that you could do it smarter, you could do it better, but you can't do it. So there was a little bit of a lack of freedom at that, at least at that time, I felt. At that time, I thought it would be a good move to go perhaps to a bigger company. So I joined a big software company that does software for mechanical engineers, worked a bit more on the commercial and the sales side, but quickly kind of got caught up in the corporate American business world and politics and those kinds of things. And really wasn't too enjoyable as well. And I think both parties found out quite quickly that we're not a good match in that sense. And then you start brainstorming a bit.

I was kiting a lot in Boston. There are plenty of good, accessible beaches, a great community, and great people. When you're on beaches, naturally, the topic comes up. Did you see my jump? Did you see how high this was? And I don't know what the exact kind of initial kickoff was, but there's always one thought that starts everything right.

There must've been a thought at one point, like, huh, couldn't we measure this somehow? So I started tinkering around with strapping a phone to the board and getting some of that data from the sensor. And we very quickly found out that it's quite doable. Then, the next question is, can you commercialise something like this?

Around this time, companies like Fitbit, Jawbone, and other wearables, Nike FitBand, for instance, came around and showed that all the components necessary to do something like this are available in a low-power consumer environment. This means that you can fit it into a small device, you have connectivity via Bluetooth, and you have enough processing to do the math.

The next step was to find a team and start a business. Two friends of mine who were kiting in Boston back then as well, I was able to convince them to quit their day jobs, just like I did, and start this venture, and off we went. It was very hard to pinpoint where exactly it started, but these things sometimes naturally develop, and I kind of felt like this was what I was meant to do at that time.

If you remember the early WOOs, 1.0 and 2.0, you’ll remember that hardware issues were often a problem. Leo was really honest in his answer to my questions on this.

There were some issues with 1.0 and 2.0, particularly with waterproofing and corrosion resistance. We had those pins on there for charging, and they would start to corrode if they weren’t rinsed in fresh water. Those early issues cost us a lot in warranties and caused us a lot of frustration. They also created a lot of unhappy customers and problems. We could have avoided a lot of these things if we were just more of a product-focused company.

In the early days, my mind was 100 % on running the business and everything that goes with it. That distracts you from the really important things, and what you learn at the end of the day is that a supplier or a third party that does design work for you will never care quite as much as you do. And so there were some hiccups, some lessons learned. However, I think with Woo 4 .0 it’s really the first time we were able, just from a pure resource standpoint, to refocus our internal resources on that physical product itself. We were really able to make sure, you know, late nights and testing, testing, testing, and all sorts of iterations and everything to ensure this thing is bombproof. So it took us a while. But yeah, it was a challenging time early on, for sure. Lots of blood, sweat and tears.

I also asked Leo about the new device and how different it was from the original. If you, like me, had an early device but gave up on it because of the issues, it was interesting to hear Leo’s answer.

I mean, it's a combination of many things. You mentioned already that technology improves. So, the two main components that we have on our electronic side are the processor and motion sensor. So how much of a workload can that processor have? Multiple factors have increased that from our first device to the new one. Then, of course, the motion sensor itself has gotten a lot, lot better. So back then there were devices that had much more noise, which were just less accurate, harder to calibrate and so forth.

That's one part, just merely the electronics is a night and day difference. You can easily say, let's take a laptop or a phone from 2013 when we started and take one from today and just look at the screens and everything, right? It's a night-and-day experience. So, it's the same internally for WOO as well. The second thing that really played a big role was the experience that we gained with the product.

All the little details on choices of materials and components are a big, big thing. So we as a team learned as well. Of course, our developers over the years had more and more data. By now, we have granular data for almost every single jump in our servers that's being transmitted because we have a better Bluetooth connection. We can do that because Bluetooth improved over the years as well.

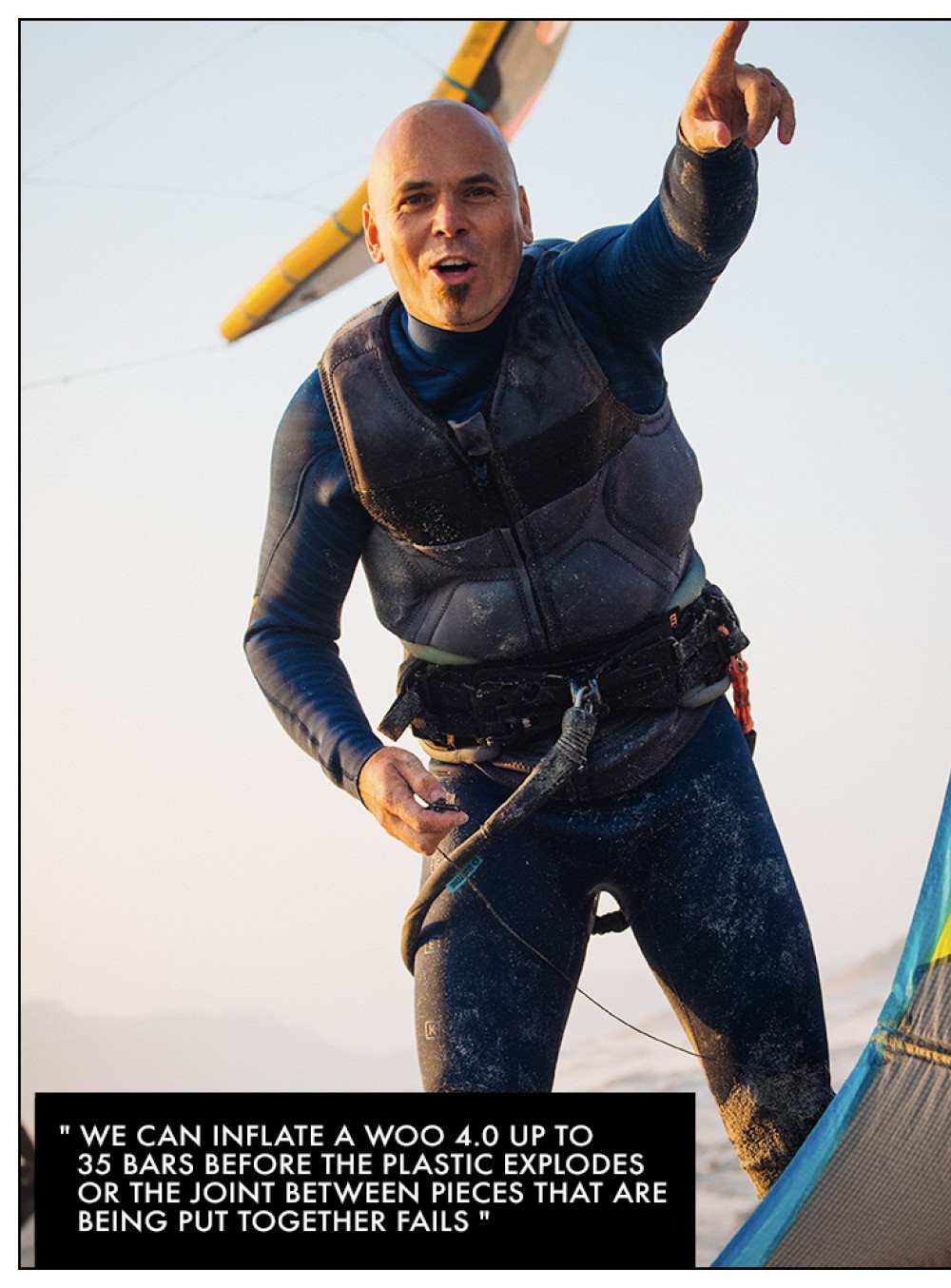

I think the biggest change, at least for me as a mechanical engineer, is the pure plastics side of things. Effectively how this device is built and how it's being sealed. We have wireless charging now, so there are no more contacts on the outside. From a glueing standpoint, we made it so much better, and this is some of the testing that we've been doing. There have been hundreds, if not thousands, of products being destroyed and tested to destruction in an effort to find the best kind of combination of materials, glue and geometry for really waterproofing them. Now we can inflate a WOO 4.0 up to 35 bars before the plastic explodes or the joint between pieces that are being put together fails; you have to wear safety glasses and duck for cover when that happens.

The frustration we had from our users was never, hey, you know, I bought your product, it's boring, can I give it back? It was always, hey, I bought your product, and I'm having so much fun. I just went on vacation to beat my record, and now it no longer works. That's just heartbreaking when you get this, you know that it's because at the end of the day, you didn't do your job. So that's the hard part.

You can't be too hard on yourself because you'll drown otherwise. But yeah, you got to at least take ownership and say, yes, that's our job. And finally, with 4.0, we had the time and the resources to do it right. And 4.0 came out exactly the way we wanted it to. So that's great. But yeah, it's a night-and-day difference between the 1.0 and the 4.0.

It was easy to see Leo’s passion throughout the interview. We chatted for 90 minutes, so this is a mere snippet of what we talked about. I asked him about cheating with the WOO and how they monitor that, as well as the darker side of the device and how it has encouraged riders to perhaps put up bigger kites in conditions they can’t handle.

We certainly covered a lot of ground, and it was a really interesting chat with a very dedicated kiteboarder who really wants to spread the fun of the WOO far and wide. It definitely changed my perception of WOO for the better. However you feel about the device, if you listen to the podcast, you’ll no doubt love it a little more after listening to Leo chat with real enthusiasm about the product he’s created.

Videos

By Rou Chater

Rou has been kiting since the sports inception and has been working as an editor and tester for magazines since 2004. He started IKSURFMAG with his brother in 2006 and has tested hundreds of different kites and travelled all over the world to kitesurf. He's a walking encyclopedia of all things kite and is just as passionate about the sport today as he was when he first started!