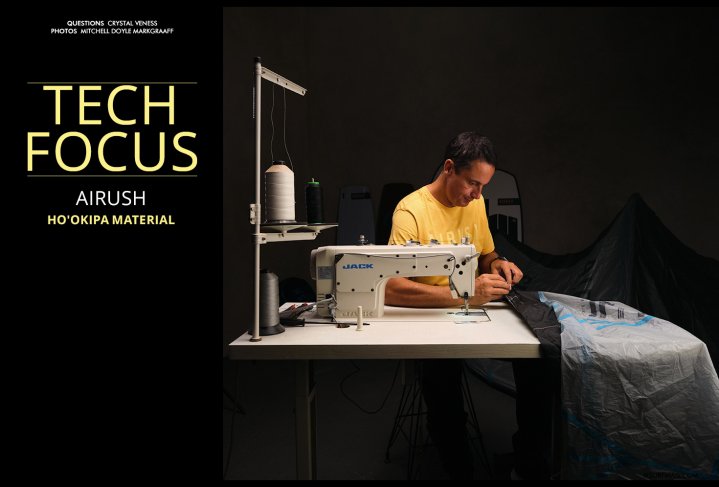

Tech Focus: Airush Ho'okipa Material

Issue 103 / Mon 19th Feb, 2024

In the materials innovation space, the development team at Airush continue to roll out their range of ultra-light kites featuring Ultra PE materials, such as Ho'okipa by Challenge Sailcloth. We caught up with the Airush team to find out what makes this material a perfect fit for their Team Series range in this Q&A!

Let's start with a general question: What is the benefit of ultra-light and ultra-strong materials in the kite industry?

Ultra-light kites generally fly better, not only in lighter winds but also when the kite is in specific positions in the wind window. A kite needs to overcome its weight, or momentum, before it can climb, turn, or respond. Therefore, the lighter you make it, the more responsive it gets.

Ultra-strong materials not only last longer for the user but can run higher pressures and tension, which also increases responsiveness. There are many factors to consider when working with composite fabrics. You do need to look beyond pure "strength", as certain materials can be stiffer and/or more responsive but might not have the same tear strength or damage tolerance.

Tell us all about the Ho'okipa fabric used in the ultralight Ultra PE Airframe of your Lithium Team, Ultra Team, and Session Team! What makes this material special?

As a base material, Ultra PE is up to 32x stronger compared directly to polyester, with the Ultra PE fiber being 15x stronger than steel at the same weight and 2x lighter than Carbon Fiber. Ultra PE fiber is so light that it floats on water. Once integrated into Ho'okipa's unique woven structure, a high amount of material in the composite is structural, allowing us to optimize all areas of the kite's construction.

Ho'okipa combines light weight with maximum durability in a leading-edge material. The Ultra PE primary woven structure offers an excellent combination of lightweight, rigidity, and durability. This allows for 50% higher pressure, creating increased stiffness combined with a thinner leading edge. This works in conjunction with the Ultra PE Load Frame, featured in all Team Series kites. The result is supercharged responsiveness coupled with sublime handling and, of course, the long-term performance you expect from Airush.

You've developed Ho'okipa in collaboration with Challenge Sailcloth; can you give us some insights into the process of discovering and testing a high-performance material such as this?

The key material that we have been incorporating into R&D over the last decade is Ultra PE (UHMWPE & UHMW) as a replacement or reinforcement for polyester to create these composite structures and materials.

We have long-standing development relationships with a few of the key cloth manufacturers, and we are continuously looking for ways to reduce weight and/or increase strength. Around 6 or 7 years ago, it was clear that we had reached the design limits of polyester as a base material if we wanted to move towards higher pressures, lighter weight, or increased durability. We would need to look at new base materials and started working with Ultra PE. These are commonly known under the brand names of Dyneema or Spectra, where Ultra PE is the base material.

We tested three different materials from three suppliers for extended trials with various formulations, and the Challenge Ho'okipa was the most ideal for our immediate application. A lot of time was spent on initial testing and optimization in development and manufacturing, and long-term testing is ongoing as we continue to explore new materials.

Let's get really technical here! How is the Ho'okipa fabric created, woven, and laminated compared to traditional Dacron fabric?

The base of Ho'okipa cloth starts off with the Ultra PE yarns. To create these, a dilute solution of UHMWPE is gel-spun into dozens of small-diameter fibers that are then combined into a predetermined yarn size for the warp and weft yarns. These Ultra PE warp yarns are then wound onto a warp beam that is then installed into a high-precision computerized loom, where the Ultra PE weft yarns are then woven into the warp yarns.

The weaving process is very similar to Dacron, although the raw Ultra PE material is much more expensive and has limited applications at this price. So, typically, the amounts made are much lower with specialist weavers, where a lot of attention is paid to getting all of the tension in the fibers as consistent as possible, along with the tension between the warp and the fill being very precise.

The finishing of Ho'okipa is, however, more complicated than with Dacron as the material can't be resin stabilized in the same way as a polyester fabric. A lightweight backing material is applied instead, which keeps the fabric stable during cutting and final assembly.

Is it necessary to adapt the design and construction of a kite when using Ho'okipa instead of traditional Dacron?

It was not only necessary, but one of the advantages is that we are able to run a much thinner leading edge at a higher pressure, resulting in a much stiffer airframe.

What are the performance gains between, for example, the Ultra and the Ultra Team using Ho'okipa fabric?

The key performance gains of Ho'okipa, coupled with the Ultra PE Airush Load Frame featuring WebTech, are improved canopy tension and rigidity for increased responsiveness and smooth handling over an extended period of time.

What is the weight difference, and what are the key differences that a kiter might feel if flying both back to back?

A 9m Ultra Team is about 8% lighter than a 9m Ultra, for example. Here, the combination of our proven Single Strut Geometry with the new narrow diameter high-pressure leading edge and high-tension canopy allows the Ultra Team to fly further forward in the window, creating the perfect balance for light wind performance.

Is there any downside to the Ho'okipa material or how the kites feel in the sky?

The only downside for us is the price of the raw material, as it's around 8 times more expensive, along with the complexity of manufacture. In the air, for the user, it's only positive.

What is the team at Airush most excited for the market to experience when trying out the Team Series kites featuring Ho'okipa?

The Team Series is a collection that showcases our kite and board models that sit at the pinnacle of all Airush products. It's a pleasure to share a range that was established to enable you to ride exactly what our Pro Team ride, without compromise, as we continue to chase the future of durable lightweight performance.

By Crystal Veness

Editor at IKSURFMAG, Crystal Veness hails from Canada but is based in South Africa. When she isn't busy kitesurfing or reporting on the latest industry news for the mag, she is kicking back somewhere at a windy kite beach or working on creative media projects.