Tech Focus: RS V9 and Master Twintip Range

Issue 109 / Wed 12th Feb, 2025

Eleveight continues to push the limits with the RS V9 and Master Twintip range. In this exclusive chat, we dive into the RS V9’s improved power, durability, and control, plus the Master Twintip’s refined construction and eco-conscious materials. You won’t want to miss this!

Hi! Thank you for taking the time to chat with us. We look forward to hearing all about the new RS V9 and Master Twintip Range. The RS has been a flagship kite for Eleveight for many years, how long did you spend developing the V9 version, and what were the design goals at the start of the project?

Development never stops—it’s true, as our R+D is a continuous process. We start the new version as soon as we finish the previous product version (in this case, the RS V8). Sometimes, we open the drawing board on a new product before its predecessor is released into the market. In other words, we’re talking about the RS V9 here, but our developers are already in full swing to develop the V10 version!

The development timeline for incremental changes, like in the RS V9, is roughly 12 months. During this time, we develop several prototype test iterations in different key locations and with different material configurations and bridle line setups. The process is quite complex, even if the final result cannot be received as something that stands out as new. However, it is quite the opposite because all the smaller invisible changes, such as new wireframes or slightly changing the aspect ratio, significantly impact performance.

Design goals all start with the target market’s needs, and riders’ riding styles and preferences are constantly changing. A freeride kite from 5 years ago had different needs than a freeride kite in the market today. By observing the market and getting very good feedback from our network, we already have a good starting point.

One design goal for the V9 was efficient power development to help with loop speed and instinctive control. Nowadays, riders want to jump high and loop their kites, so making this efficient and easy for the rider was a big goal. Our secondary goal was to tune the power development to increase the low end of the RS V9. This helps ensure a wide wind window, as not all riders have four kites in their quiver.

These days, more ‘radical’ riders also need a product with more durability, so we also aimed to increase the kite’s stability and efficient load transition. We used new X6 ripstop material in specific key areas and worked on the wireframe to set up the different panels for the best possible load distribution. We also made some changes on the leading edge to ensure extra durability so that the inflatable part could tackle more load.

Lastly, the modern rider demands a broader variety of trim options for the kite. We also aimed to improve our turning speed setting so customers can trim the kite how they want to ride it.

The RS V9 is marketed to reduce the need for a large quiver due to its wider wind range. How was this achieved, and what’s the ideal quiver for the average rider out most weekends with a wide range of conditions?

The question of an ideal quiver is a personal decision based on location, rider ability and weight. In general, three kites will cover 95% of your sessions, but with an RS, you can also have only two kites in your quiver, which will cover most of your days. Our top selling sizes are 9m and 12m, so that gives a good indication.

The RS is a classic delta/hybrid 3-strut kite, and its DNA generally has a broader wind range. The RS’s 3-strut construction is light and agile, which helps in low-wind conditions. However, it also offers a lot of depower, so the kite also performs well in the higher wind range.

For the V9 version, we worked on a moderate increase in the leading edge arc with a higher projected area to improve power development and increase the low end. We also focused on further weight reduction using our new X6 ripstop material on the trailing edge and wing tips to improve load transition and reduce material weight.

The larger models (14m and 17m) use XT Light material to enhance responsiveness and reduce weight. What are the weight savings over the XT material used on the smaller sizes, and how does this impact the overall durability and longevity of the kite?

The weight savings from XT light are 15% if you compare both materials, so if you translate that into the overall kite weight, we have a weight advantage of 10% in the bigger sizes. That ratio would decrease in smaller sizes, which is why we prefer to use it only in bigger sizes.

However, the more important factor than weight is the increased performance. XT light offers a perfect balance between stability and stiffness and is key for bigger kites, as it is essential they are also responsive. The times when bigger kites were just low-end pull machines are over. We want a fun reactive kite that applies to bigger sizes that can loop and feel playful.

The increased stiffness also helps the overall durability of the kite recover quicker after jumps and loops, as the canopy has better overall tension and load distribution. That all helps to keep the canopy crispy for longer and increase the life span of the RS.

How did integrating Teijin’s X6 ripstop material improve the kite’s performance and durability compared to previous versions? Is this new material heavier than X4?

We used the X6 first in our wing models and had fantastic results with the overall tension of the canopy and less deforming in the trailing edges. In the previous version, we also used X4 to transition between the inflatable structure and the canopy. These areas are under high stress because a harder material like Dacron is linked to a softer material like ripstop. The load transition between these two materials is not easy and can lead to stress areas where the kite can rip. For this reason, we always used a 2-step load transition, which is a double layer of X4 ripstop (a small strip between the inflatable structure and the canopy ripstop), and our new X6 ripstop follows the same principle.

Due to its woven structure, the X6 is slightly heavier overall. Still, it offers 30-40% less elongation, which is very beneficial in stress areas like the load transition zones and the trailing edge. A better load transition increases the kite’s performance and also improves durability. Even though the X6 is a bit heavier, we reduced the material consumption in these stress areas, which led to a lighter overall construction.

With all these new material innovations, how does the RS V9 compare to the RS Pro? Has the gap been closed from the V8, or are they still in a different ballpark in terms of performance?

Overall, we aim for different performance and target markets, the gap between both kites. Tthe two kites. Ourvelop kites that offer the right performance for the needs of different riders.

The RS V9 has very intuitive flight performance and is our classic plug-and-play freeride kite that is very versatile. It is also a kite that has a reasonable price point for most. In comparison, the RS Pro is more like high-performance racing skis that are more dynamic, reactive, and fast, but the rider also needs more skill to use the performance advantage.

The leading edge arc was adjusted for better power development and low-end performance. What kind of rider feedback or testing led to this decision?

I mentioned this a bit in the beginning, as all new Eleveight developments are a mix of observation, feedback from the market and our research for new shapes and materials. Our decision to modify the leading edge arc was mainly driven by achieving very easy and accessible power development, which is required for modern freeride kites. Most freeriders these days are focused on jumping with some added tricks or even kiteloops, and on helping them progress, we wanted the RS V9 to have an increased turning speed noticeable in loops. Fast-turning kites are also very good in the low-end segment. The kites swing faster, and you can generate much more power in low wind conditions.

How does the RS V9 maintain stability and control during gusty winds, and are there specific bridle settings riders can tweak for extreme conditions?

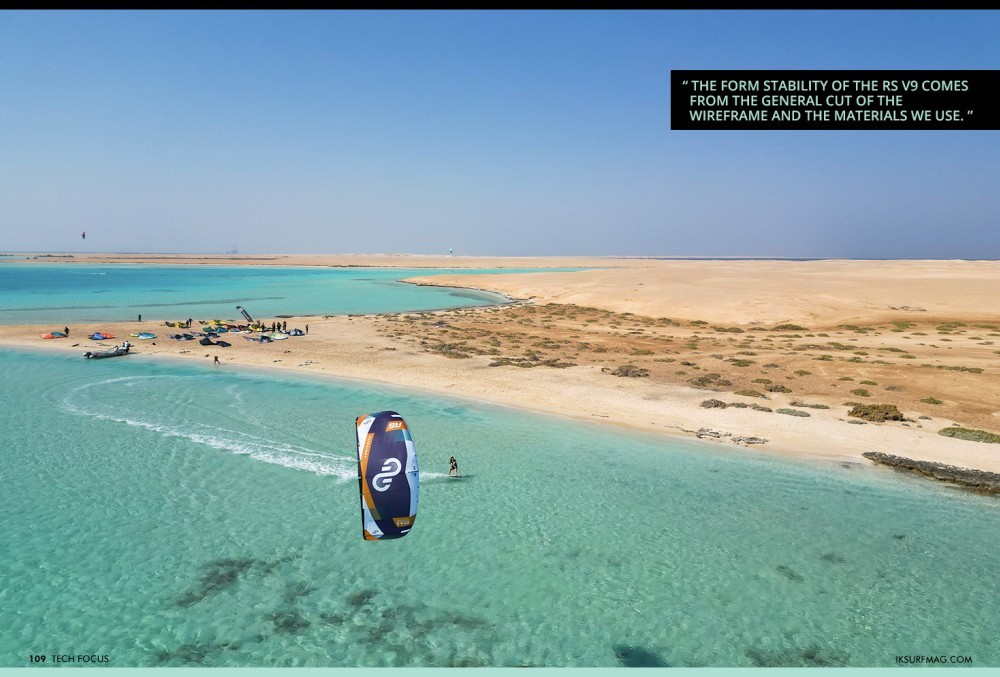

All of our Eleveight kites have been designed to focus on stability as kites nowadays have to tackle much more load from the riders. Our sport has progressed in the last 10 years, and so has most kiters. The form stability of the RS V9 comes from the general cut of the wireframe and the materials we use. The X4 ripstop, the previously mentioned X6 ripstop for the 2-step load frame, and our high-quality XT inflatable material all build a foundation for a solid construction. As a result, the kite is agile and fast but has less deformation under load, which can be an issue, particularly in gusty conditions.

We also offer three bridle settings on the RS to offer personal preference depending on how you ride, and not so much that one is better for gusty winds than the other. The wave setup increases the drift ability, and the turn is more of a pivot with less power, which performs best in gusty conditions. The kite develops a bit less power, which may be helpful for most riders. However, if you want to get a bit more extreme, then our standard freeride setting allows the rider to go big and pull off some insane hang time and loops if you have the guts!

Who is the RS V9 for? What riders will benefit most from the new performance upgrades? Is it suitable for everyone or better for more advanced riders?

Hands down, the RS is made for versatility and is aimed at the classic freerider. In other words, it’s our all-round powerhouse guaranteed to get you stoked from your first launch. To be more specific about the V9 version, we hope the upgrades will help most riders progress in their air game. Loops were never easier than with the V9 version, and the hang time is guaranteed!

Master

Again, you have three versions of the Master Twin tip: the V8, S V5, and C+ V7. Did they all get a complete redesign for 2025 and share the same shape, or did they have to be tweaked according to the different construction materials and use case scenarios?

Our new Master range is completely redesigned in terms of the shape, but also about the material mix and construction. Franz Schitzhofer, our board designer, went through several prototypes and many testing hours to find the right balance for each board.

In general, the shape and rocker of the Master, Master S, and Master C+ are the same, but the differences are in the construction, flex patterns, weight, and performance outcomes.

The Master V8 is our base model with a medium to hard flex performance for the freerider and a lot of freestyle potential. The Master S is the little sister and is tweaked for lighter riders. The flex is softer based on a thinner wood core. We also changed the inserts so you can ride with a smaller stance. The Master C+ is a complete carbon construction, which decreases the board's overall weight but also gives it very dynamic flex and pop... it’s tweaked for the performance freerider that likes to go big and push the limits in big air.

You’re using basalt fibres, which are more ecologically friendly than traditional carbon. Have there been any other green initiatives in the board production?

We used basalt last year for the Stellar and were impressed with its performance. We should implement it immediately into our Master range as well. This high-tech material is suitable for our board range and has an ecological advantage. It feels better to push design to produce more sustainable products.

All our boards have a different resin implemented, too. GreenPoxy is a clear bio-based epoxy resin with 35% plant-derived content, offering lower carbon emissions and excellent colour enhancement for prints. Its high impregnation properties reduce resin use, making boards lighter. We also use sustainable Paulownia wood core, a fast-growing wood with a rapid absorption of atmospheric carbon dioxide.

Lastly, our twintip range is wrapped in plastic-free packaging and produced in Europe, decreasing shipping and ensuring that the factories have a high standard in energy and waste management.

We would be lying if we said the Master is an ecologically friendly product. Our industry relies on oil-based raw materials, so we must avoid greenwashing. However, as a brand, we try to be mindful of all the challenges of sustainable production and change things when we can 100% control them.

What sort of rider should be looking at each version of this board? The S V5 is better for smaller riders, but what separates the C+ V7 and V8? What advantages and disadvantages are there between the three shapes?

The three different models are based on rider preference. The Master S is made for smaller riders and helps them find a board that fits their weight. Its narrower stance, softer flex pattern, and smaller size will help riders progress and prevent them from being held back when pushing their limits.

The Master V8 is our flagship board and offers the best versatility between aggressive freeride and freestyle. Since our test team tweaked it more in this direction, it might be the better alternative for freestyle-driven riders.

The Master C+ is for an advanced freerider who needs a dynamic and reactive board. Its state-of-the-art construction best suits boosters who focus on jumping high.

When will these new products be available, and will riders be able to demo them soon?

Our new twintip range is already in our warehouse, and our dealers are getting pre-orders! The official release will be mid-March, when customers can get their hands on one of the new Masters.

Excellent, thank you so much for your time!

Thank you, Rou!

By Rou Chater

Rou has been kiting since the sports inception and has been working as an editor and tester for magazines since 2004. He started IKSURFMAG with his brother in 2006 and has tested hundreds of different kites and travelled all over the world to kitesurf. He's a walking encyclopedia of all things kite and is just as passionate about the sport today as he was when he first started!